Timbermark has new products available that are ideally suited to coding and marking in the plastics industry.

In particular, the introduction of UV-curing has opened up opportunities to print on plastics, replacing the traditional methods, such as marking with Continuous Inkjet, or CIJ.

CIJ produces a dot-matrix-type code using a solvent-based ink. These types of printer can be difficult to keep operating reliably, and the print effect is mostly limited to logos and codes that can be printed with a 16-dot high matrix. Additionally, the code can be cleaned off with a solvent.

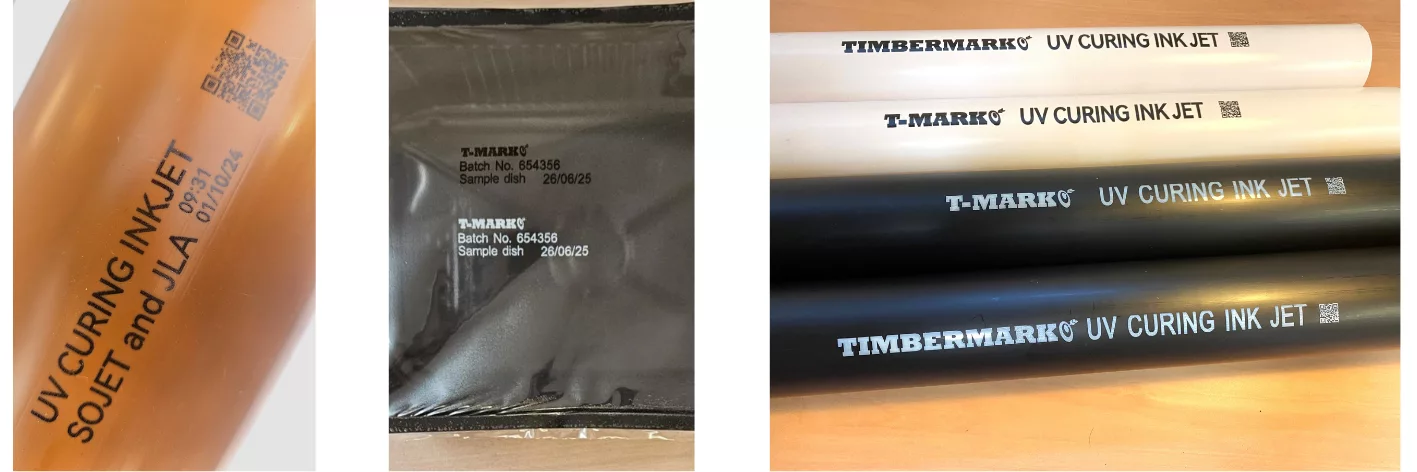

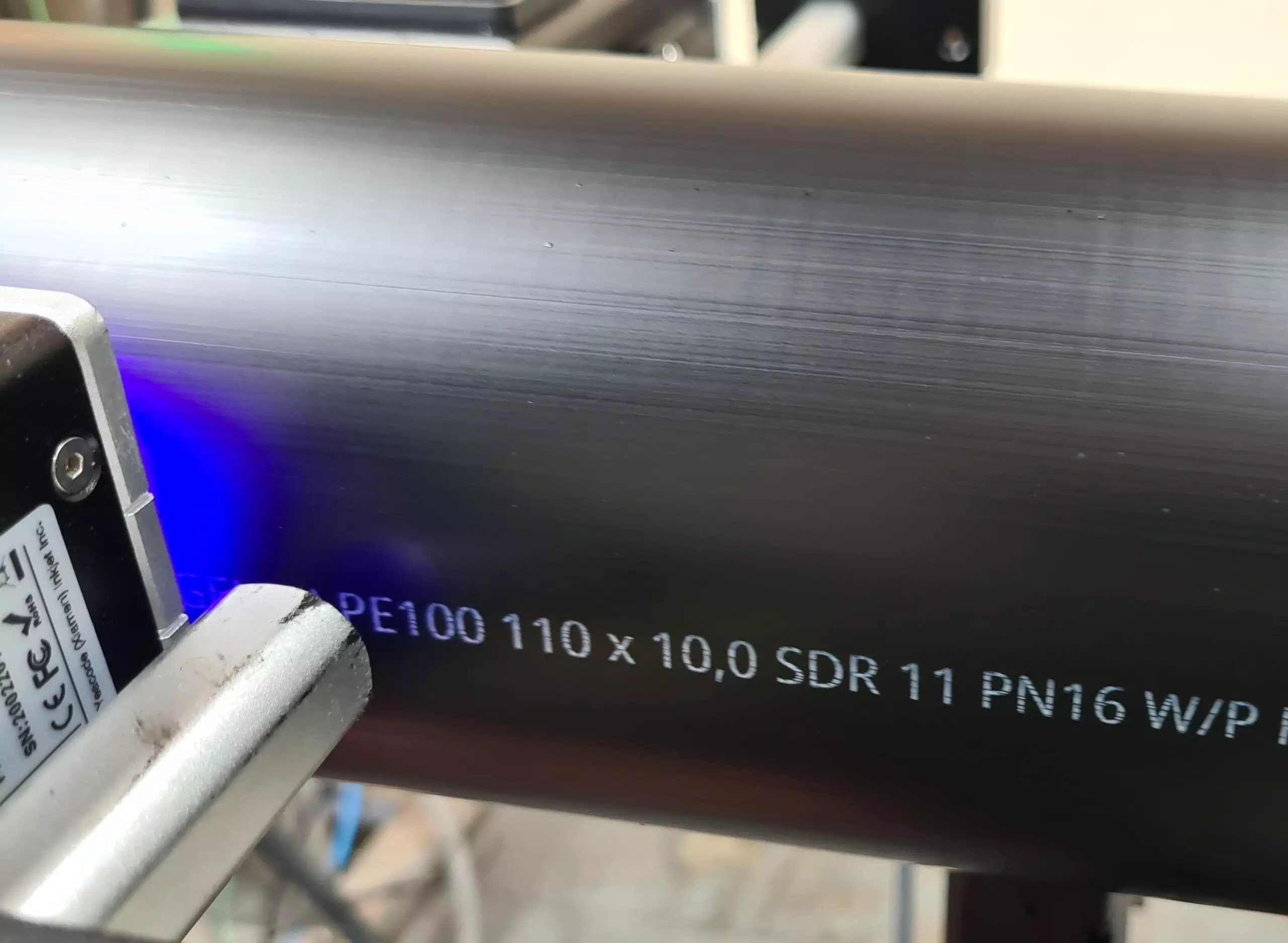

The Timbermark system, by contrast, can include plasma treatment, inkjet printing, then UV curing. The plasma treatment is usually only needed for PE products, and keys the surface of the extrusion to give good adhesion of the ink. The inkjet is high definition, and can include sharp logos, bar codes and QR codes or other detailed information. The UV-curing turns the liquid ink into a solid polymer film, that adheres to the substrate.

The cured ink cannot be removed with solvent, even MEK or petroleum. This makes it suitable for ENATS requirements. Oil and gas industry applications benefit from the durability.

With plasma treatment, the mark is difficult to remove, as the ink is keyed to the surface. This makes the print abrasion-resistant, so it can be used in underground applications, and does not degrade with handling.

When the ink is then cured with a UV LED that is about 250 x stronger than the UV in sunlight, the print is protected from fading on exposure outside.

So the result is a high definition print, that is solvent resistant, light fast and abrasion proof.

The Egeplast project enabled that customer to produce ENATS-compliant product, and this opened up a new market for them.

A project for a subsea engineering company replaced an inkjet and laser system which was illegible on the PE extruded surface. Now the customer prints their logo and a QR code that is linked to their web site.

A new project at a plastic pipe manufacturer prints customer logos onto extruded profiles in white ink onto black pipes. They also use the outline font, a feature in the newest range of printers, that allows economic ink use by printing the outline rather than a block filled character.

Timbermark can supply printers to print on substrates of different materials including plastic film lids, labels, containers, pipes and boards. As well as fixed position installations, we also supply a range of handheld printer that can use solvent-based inks for printing on plastics.

Whatever plastic surface you are printing onto, Timbermark has the solution.